Sodium thioglycolate is an important flotation inhibitor. It can be used as an inhibitor of copper minerals and pyrite in the flotation of copper and molybdenum ores, which has obvious inhibition effect on copper, sulfur and other minerals, and can effectively improve the grade of molybdenum concentrate. Sodium thioglycolate, as an effective inhibitor of a new type of sulfide ore, has been successfully applied in molybdenum production for many years. It has the advantages of less dosage, simple and convenient usage, better cost saving and economic benefit increase. It not only improves the quality of the product, but also has no pollution and no toxicity, and has completely replaced the highly toxic inhibitor sodium cyanide, which has played a positive role in environmental protection of the production area. This product can also be used as a hair removal agent.

Physikalische und Chemische Eigenschaften

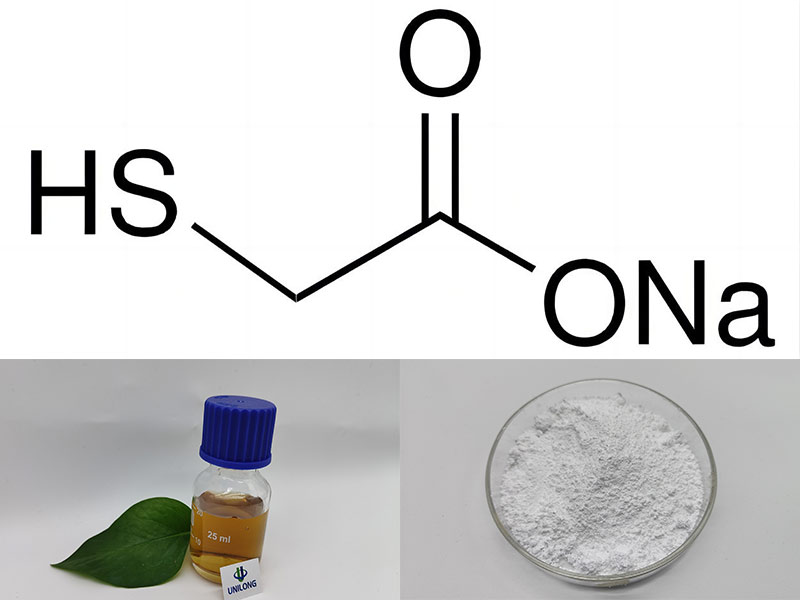

The sodium thioglycolate produced by the company is colorless to red (some slightly darker) transparent liquid, with a purity of 20%, 30%, 45% or more. There is also a white or white crystalline powder with a purity of 98% and excellent quality. With advanced technology and excellent process refined, has been sold to Henan, Shaanxi, Fujian, Liaoning and other places, foreign customers are mainly in Vietnam, India, Indonesia, Turkey, Brazil, Peru, the United States and other countries.

Preparation method

- Add a certain amount of water to a 1000mL beaker, add solid soda ash at room temperature, stir for 30 minutes to fully dissolve it, and then add chloroacetic acid for neutralization. The neutralization reaction of chloroacetic acid is exothermic, accompanied by the release of a large amount of carbon dioxide gas, the reaction is relatively drastic, in order to control the temperature of the neutralization reaction (the temperature is too high, the temperature is too high, the temperature is too high, the temperature is too high. Chloroacetic acid will undergo hydrolysis reaction to produce hydroxyl carboxylic acid) and prevent foam overflow during the reaction, the addition rate of chloroacetic acid is slow, and its dosage depends on the pH value of the solution; After the solution becomes clear, pour it into a three-port flask and put it into an electric heating water bath for heating reaction. When it reaches a certain temperature, add sodium thiosulfate crystal, stir and heat up to 85℃, and react at this temperature for 40 minutes to obtain salt. After the temperature continues to rise to 95℃, the strong alkali thioglycolating agent solution is added, the reaction is about 40min, the heating and stirring are stopped, the natural cooling is done, and the transparent sodium thioglycolate product can be obtained after purification.

- Add 185g sodium chloroacetate,29g isopropyl xanthoxanthate and appropriate amount of water into a 500ml four-mouth flask, react at 75℃ for 2h, then drop to room temperature, and slowly add 5% excess monoethylamine into the four-mouth flask with stirring. After the addition, the temperature is raised to 70℃ and the lh is kept warm. At this time, the reaction system changes from transparent to yellow cloudy, and finally becomes brown cloudy liquid. Stop stirring, stand stratification, the upper layer is yellow transparent liquid, which is ethylthiamine vinegar, said the mass is 77.1g, the purity is greater than 96%, the isopropyl alcohol mass fraction is less than 3.0%; The lower layer is dark red alkaline waste liquid, containing sodium leucyl acetate, sodium chloride, etc., which can be directly used as flotation agents.

Anwendung

1. Application in the separation of copper and lead Sodium thioglycolate, as a non-toxic, small molecule inhibitor, has a good inhibition effect on chalcopyrite, and can be applied in the separation process of copper-lead mixed concentrate to achieve the separation of copper and lead. Factors such as the dedrug effect, the type and dosage of the collector, the pulp p and H value, and the amount of sodium thioglycolate during separation have important effects on the separation effect of copper and lead, but the amount of sodium thioglycolate is the most important influencing factor. When the amount is appropriate, the separation of copper and lead can be better achieved. When the amount is too large, sodium thioglycolate can inhibit both of them. Inhibition mechanism: The infrared spectral curves of sodium thioglycolate after the interaction with chalcopyrite and galena were bifurcated. After washing, the absorption valley of these characteristic groups became weak but did not disappear completely, which proved that sodium thioglycolate coexisted with physical adsorption and chemisorption on chalcopyrite and galena surface.

2. Activated sphalerite with copper sulfate in high pH slurry, lime as an inhibitor of pyrrhotite and pyrite, supplemented by sodium thioglycolate, can effectively achieve zinc-sulfur separation, industrial production test obtained grade 45.10% zinc concentrate, operation recovery of 94.39%. Sodium thioglycoacetate is a medium toxic agent, which has a good inhibition effect on pyrite and pyrrhotite, and can completely replace highly toxic cyanide to achieve cyanide-free separation process of zinc and sulfur, which not only ensures the production index of zinc concentrate grade and recovery rate, but also can meet the national environmental protection requirements. Sodium thioglycolate has little inhibitory effect on sphalerite, and has maintained good production index since the use of sodium thioglycolate.

At present, according to the needs of customers, we have opened a new production line, all using high-purity imported raw materials production, sodium thioglycolate widely used in hair removal (such as leather, human body), hair ironing and dyeing agent, solid and liquid media preparation.