The environment provides necessary resources and conditions for our livelihood and development. With the development of society and the improvement of people’s awareness, protecting the environment has become a common goal for everyone.

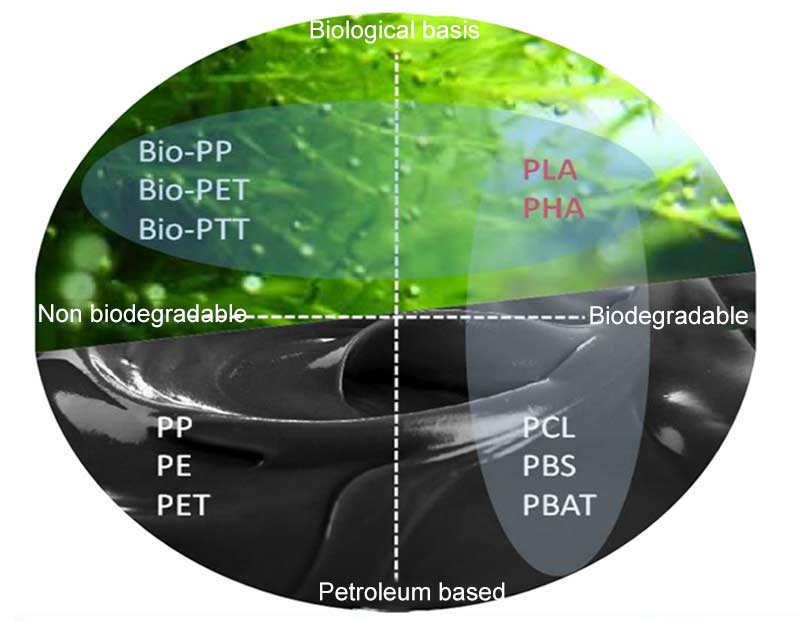

In recent years, issues such as “white pollution” and “microplastics” have received widespread attention from society, and the main reason for this problem is mainly due to the widespread use of plastic products. Most of the plastic products used in daily life are petroleum based plastics that are difficult to degrade. Due to their non degradable materials, they have brought a burden to our natural environment, and their pollution control is also a global problem!

However, plastic products are ubiquitous in our lives, and therefore, biodegradable plastics are gradually becoming a new trend. Scientists have proposed a new concept of ‘originating from nature and returning to nature’. Developed biodegradable polylactic acid (PLA) through the conversion of corn and other grains This plastic, which is converted from plant starch, has excellent biodegradability and is environmentally friendly due to its preparation process that eliminates environmentally friendly petrochemical raw materials.

What is polylactic acid?

Polylactic acid, abbreviated as PLA, also known as polylactide, CAS number (26023-30-3/26100-51-6), is mainly produced by plant fermentation. Its main components include renewable resources such as corn and wheat, so polylactic acid has good biocompatibility and biodegradability. Waste polylactic acid can be decomposed into CO2 and H20 under microbial action or composting conditions. There is no pollution to the air and soil, and it is also beneficial for promoting the light and function of plants. Polylactic acid (PLA), as a biodegradable material, is mainly used in food packaging and pharmaceuticals. The application of polylactic acid not only promotes the development of various fields, but also meets the requirements of building a green and environmentally friendly society.

Specifications of biodegradable materials:

| Biodegradable plastics | Melting point ℃ | Tensile strength MPa | Elongation% | Degradation rate | Oxygen barrier | Water vapor barrier | Application direction |

| PLA | 130-180 | 60 | 6 | Moderate | Ordinary | Ordinary | Hard packaging, disposable tableware, film bags, fiber fabrics, 3D printing |

| PBS | 120 | 40 | 400 | Fast | Unknown | Unknown | Tableware, straw, modified by blending with PLA |

| PBAT | 120 | 18 | 750 | Moderate | Poor | Poor | Soft packaging with film bags |

| PPC | – | 13 | 650 | Moderate | Higher | Higher | Thin film class |

| PCL | 60 | 20 | 300 | Slow | Ordinary | Ordinary | Surgery and medical field, film industry, other fields |

| PHA | 145 | 30 | 10 | Fast | Higher | Higher | Thin film class |

| PGA | 225 | 80 | 10 | Ultrafast | High | High | Medical field, rapid degradation products |

Application and Development of PLA

PLA is actually not unfamiliar, and you may encounter it in various aspects of your life.

From the perspective of food, with the rapid development of the delivery, express delivery, and catering industries in recent years, the commercialization of PLA products has made great strides forward. In addition to paper straws, PLA straws are also commonly used when drinking milk tea in our daily lives.

From a clothing perspective, PLA clothing made by blending PLA with antibacterial agents is favored by consumers.

From the perspective of daily use, PLA, which has been plasticized and toughened, can be applied to daily necessities and children’s toys to effectively prevent children from ingesting harmful plastic particles.

From a medical perspective, by improving the hydrophilicity and biocompatibility of PLA and strengthening the control of PLA degradation time, biomedical polymers such as PLA vascular stents, absorbable materials, and surgical sutures have gradually been put into use.

In addition, materials such as PLA plastic film and sand barrier have a broad market, which is of great significance for environmental governance and has a very large application market.

The popularization of PLA can effectively reduce the use of non degradable plastics, which is of great significance for the treatment of plastic pollution.