In modern industries, advanced raw materials play a key role in improving performance, efficiency, and durability. One such important chemical is titanium butoxide, also known as Tetrabutyl Titanate, Titanium(IV) butoxide, or Tetra-n-butyl orthotitanate (CAS 5593-70-4). This titanium alkoxide compound is widely used in coatings, paints, adhesives, and polymer production due to its strong reactivity and ability to enhance material properties.

In this article, we will explore what titanium butoxide is, its main applications, market trends, and why choosing reliable Tetrabutyl Titanate suppliers is crucial for your business.

I. What is Titanium Butoxide?

Nome químico: Titanium butoxide

Sinônimos: Tetrabutyl Titanate, Titanium(IV) butoxide, Tetra-n-butyl orthotitanate

CAS number: 5593-70-4

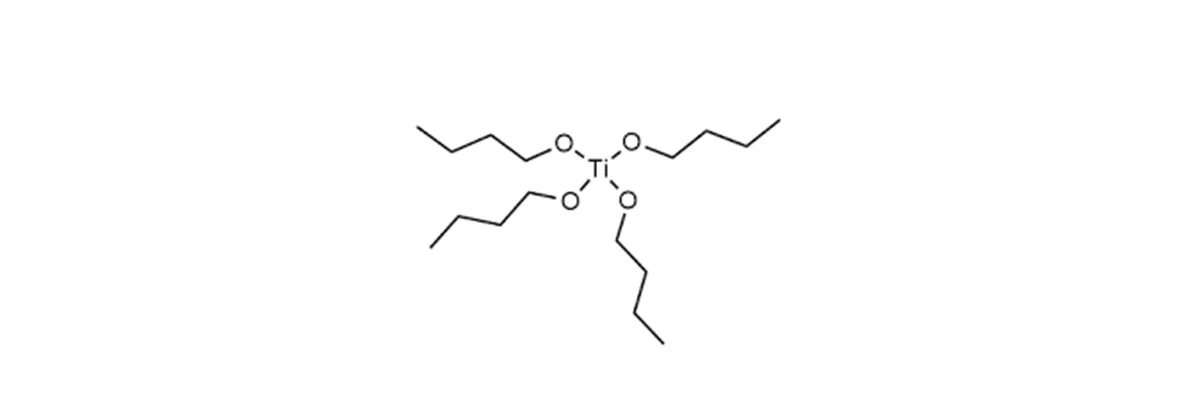

Fórmula química: Ti(OC₄H₉)₄

Titanium butoxide is a clear to pale yellow liquid that reacts strongly with water. When exposed to moisture, it hydrolyzes rapidly, forming titanium dioxide (TiO₂). This characteristic is the basis of its widespread use in sol-gel chemistry, catalysis, and thin film coatings.

Key Characteristics

High reactivity: Enables fast hydrolysis and condensation, critical in sol-gel processes.

Excellent bonding ability: Strong interaction with inorganic and organic substrates.

Versatility: Used across industries ranging from coatings to polymer catalysis and electronics.

Unlike other titanium alkoxides, Titanium(IV) butoxide offers a balance of reactivity and stability, making it easier to handle while still delivering strong performance.

II. Applications of Titanium Butoxide in Coatings

1. Role in Sol-Gel Coatings

One of the most important applications of Tetrabutyl Titanate is in sol-gel technology. Through controlled hydrolysis and condensation, titanium butoxide serves as a precursor to titanium dioxide films. These films provide:

- High transparency, making them suitable for optical coatings and glass treatments

- Strong adhesion to surfaces, ensuring long-lasting performance

- Hardness and wear resistance for protective coatings

In industries such as construction, electronics, and automotive, sol-gel coatings produced with titanium butoxide help create surfaces that resist scratching, weathering, and corrosion.

2. Titanium Butoxide in Paints and Protective Coatings

Beyond sol-gel films, Titanium(IV) butoxide (CAS 5593-70-4) is widely used in paint and coating formulations. Its benefits include:

- Enhanced gloss and surface finish, giving coatings a smooth, attractive appearance

- Durability against environmental stress, including UV radiation and moisture

- Improved corrosion resistance, critical for metals exposed to harsh conditions

- Thermal stability, allowing coatings to perform even in high-temperature environments

For these reasons, titanium butoxide is frequently added to architectural paints, marine coatings, automotive protective layers, and industrial finishes.

III. Applications of Titanium Butoxide in Polymer Production

1. As a Catalyst in Polymerization

In the field of polymer chemistry, Titanium(IV) butoxide acts as a catalyst in processes such as:

- Polyester synthesis

- Polyolefin production

- Polyurethane modification

Its catalytic activity accelerates polymerization reactions, making production more efficient while also offering greater control over molecular weight distribution. This leads to polymers with predictable properties and improved performance.

2. Enhancing Polymer Material Properties

When incorporated into polymer systems, Tetrabutyl Titanate contributes to:

- Improved flexibility and toughness, especially in engineering plastics.

- Better thermal stability, making polymers suitable for demanding applications.

- Enhanced adhesion and bonding, particularly useful in composites and specialty plastics.

This makes titanium butoxide a valuable additive for manufacturers of packaging materials, automotive parts, and electronic components.

IV. Global Demand Trends

Demand for Titanium(IV) butoxide (CAS 5593-70-4) is growing steadily. According to industry data:

- The coatings and paints sector remains the largest consumer.

- Polymer manufacturers are increasingly adopting titanium butoxide as a catalyst.

- The electronics and renewable energy industries are exploring its use in high-tech thin films and functional coatings.

This steady expansion highlights why businesses need reliable Tetrabutyl Titanate suppliers to ensure a stable supply.

V. Choosing Reliable Tetrabutyl Titanate Suppliers

1. Why Supplier Selection Matters

Since titanium butoxide is highly reactive and sensitive to impurities, working with trusted Tetrabutyl Titanate Suppliers ensures:

- Consistent product purity that meets industrial and laboratory requirements.

- Technical documentation, including Certificates of Analysis (CoA) and safety data sheets.

- Batch-to-batch stability, critical for maintaining production quality.

2. What to Look for in a Supplier

When sourcing Tetra-n-butyl orthotitanate, companies should consider:

- Supplier experience in international markets.

- Capability to provide both bulk and small-scale packaging.

- Competitive and transparent pricing, with no hidden costs.

- Availability of technical support to guide safe handling and applications.

Choosing the right partner helps avoid risks such as inconsistent quality, supply interruptions, or regulatory issues.

VI. Safety, Storage, and Handling of Titanium(IV) Butoxide

1. Storage Recommendations

- Store in a cool, dry place, away from humidity.

- Keep containers tightly sealed to avoid hydrolysis.

- Use stainless steel or coated containers to prevent contamination.

2. Safety Guidelines

Always wear gloves, goggles, and protective clothing when handling.

Work in a well-ventilated area to avoid inhalation of vapors.

In case of spills, absorb with inert material and dispose according to local regulations.

Proper handling not only ensures worker safety but also preserves the integrity of the product.

VII. Why Choose Us as Your Tetrabutyl Titanate Supplier?

As an experienced supplier of Titanium(IV) butoxide, we provide:

- High-purity Tetrabutyl Titanate (CAS 5593-70-4) that meets international quality standards.

- Competitive tetrabutyl titanate price for both small and large orders.

- Custom packaging solutions to protect against moisture and extend shelf life.

- Dedicated customer support for technical guidance and logistics arrangements.

Whether you need bulk shipments for industrial applications or small quantities for research and development, we can deliver tailored solutions that fit your requirements.

VIII.Conclusão

Titanium butoxide (Tetrabutyl Titanate, Tetra-n-butyl orthotitanate, CAS 5593-70-4) is a powerful chemical that enhances the performance of coatings, paints, and polymers. Its ability to act as both a precursor and a catalyst makes it indispensable in industries where quality and durability are critical.

By choosing reliable Tetrabutyl Titanate suppliers, businesses can secure consistent quality, competitive pricing, and dependable technical support. If you are looking for a trusted source of Titanium(IV) butoxide, contact us today to request samples, check the latest tetrabutyl titanate price, or discuss customized solutions for your project.