마지막 업데이트 2024년 6월 26일

이 개인정보 보호정책은 다음의 정책을 설명합니다. Unilong Industry Co.,Ltd., 산둥성 화학공업단지. 이메일: info@unilongindustry.com, 핸드폰: +86 18653132120 귀하가 당사 웹사이트를 사용할 때 당사가 수집하는 귀하의 정보의 수집, 사용 및 공개에 관하여 ( https://unilongindustry.com/ ). (이하 "서비스"). 서비스에 액세스하거나 서비스를 사용함으로써 귀하는 이 개인정보 보호정책에 따라 귀하의 정보 수집, 사용 및 공개에 동의하는 것입니다. 귀하가 이에 동의하지 않는 경우, 서비스에 액세스하거나 서비스를 사용하지 마십시오.

당사는 사전 통지 없이 언제든지 이 개인정보 보호정책을 수정할 수 있으며, 개정된 개인정보 보호정책을 서비스에 게시합니다. 개정된 정책은 개정된 정책이 서비스에 게시된 날로부터 180일 후에 유효하며, 해당 기간 이후에도 서비스에 계속 액세스하거나 사용하는 경우 개정된 개인정보 보호정책을 수락한 것으로 간주됩니다. 따라서 이 페이지를 주기적으로 검토하는 것이 좋습니다.

사용

당사는 귀하가 요청한 서비스를 제공하고, 귀하와 소통하고, 문제를 해결하고, 귀하의 경험을 맞춤화하고, 당사의 서비스와 웹사이트 업데이트를 알리고, 당사의 웹사이트와 서비스에 대한 관심을 측정하기 위해 귀하의 개인 정보를 사용합니다.

많은 웹사이트와 마찬가지로, 당사는 귀하의 경험을 향상시키고 방문자와 당사 웹사이트 방문에 대한 정보를 수집하기 위해 "쿠키"를 사용합니다. 쿠키와 쿠키 사용 방법에 대한 정보는 아래의 "쿠키를 사용합니까?" 섹션을 참조하세요.

폭로

귀하의 명시적 동의 없이는 귀하의 개인 정보를 마케팅 목적으로 제3자에게 판매하거나 임대하지 않습니다. 당사는 법적 요구 사항에 대응하고, 정책을 시행하고, 게시물이나 기타 콘텐츠가 타인의 권리를 침해한다는 주장에 대응하거나, 모든 사람의 권리, 재산 또는 안전을 보호하기 위해 개인 정보를 공개할 수 있습니다. 이러한 정보는 해당 법률 및 규정에 따라 공개됩니다. 당사는 또한 당사의 사업을 수행하는 데 도움이 되는 서비스 제공업체 및 공동 콘텐츠와 서비스를 제공하고 잠재적으로 불법적인 활동을 탐지하고 예방하는 데 도움이 될 수 있는 당사의 기업 가족 구성원과 개인 정보를 공유할 수 있습니다. 당사가 다른 사업체에 합병되거나 인수될 계획인 경우, 당사는 다른 사업체와 개인 정보를 공유하고 새로 결합된 사업체가 귀하의 개인 정보와 관련하여 이 개인정보 보호정책의 조항을 준수하도록 요구할 수 있습니다.

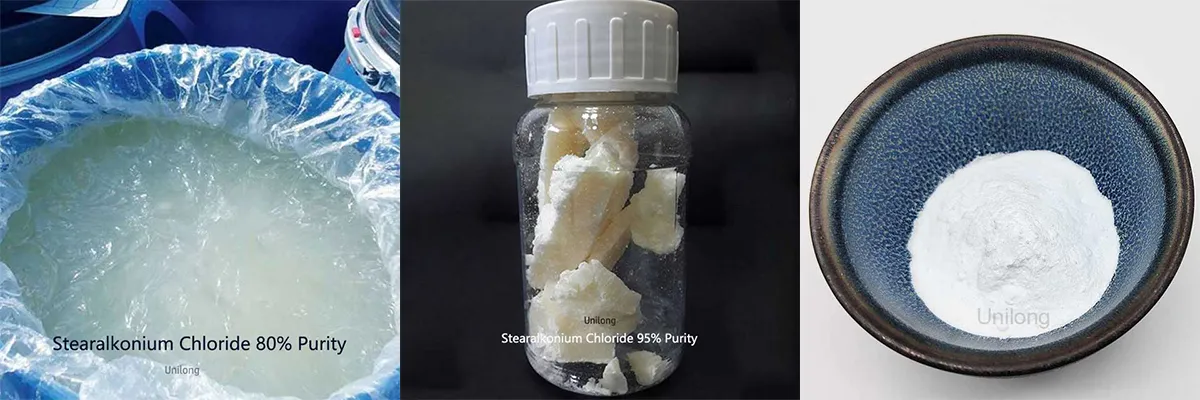

메디아

웹사이트에 이미지를 업로드하는 경우, 웹사이트 방문자는 웹사이트에 있는 이미지에서 모든 위치 데이터를 다운로드하고 추출할 수 있습니다.

사용 권한

언제든지 저희에게 연락하여 귀하가 저희에게 제공한 개인 정보에 접근하거나 업데이트할 수 있습니다. info@unilongindustry.com.

보안

우리는 정보를 보호해야 할 자산으로 간주하고, 귀하의 개인 정보를 무단 액세스 및 공개로부터 보호하기 위해 여러 도구를 사용합니다. 그러나 아시다시피, 제3자가 전송 또는 개인 통신을 불법적으로 가로채거나 액세스할 수 있습니다. 따라서 귀하의 개인 정보를 보호하기 위해 매우 열심히 노력하지만, 귀하의 개인 정보 또는 개인 통신이 항상 비공개로 유지될 것이라고 약속하지 않으며, 귀하도 기대해서는 안 됩니다.