PLGA is copolymerized by lactic acid (LA) and glycolic acid (GA), which can make full use of the advantages of PLA and PGA and make up for their respective shortcomings. The obtained PLGA has good degradability, biocompatibility and outstanding mechanical properties, heat resistance, and degradation controllability, making it the first batch of degradable medical polymer materials certified by (FDA), and is widely used in drug controlled release, medical fiber materials, bone tissue engineering scaffolds and other fields.

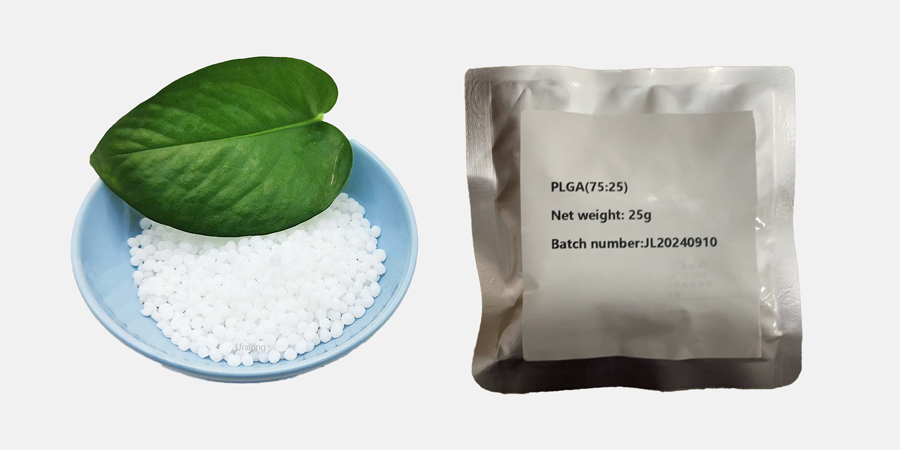

PLGA is usually a white solid with a glass transition temperature between 40 and 60 °C. It is in a glassy state at room temperature. The molecular chain shows strong rigidity and is generally an amorphous or semi-crystalline polymer.

The degradation performance of PLGA mainly depends on the copolymer monomer ratio, crystallinity, relative molecular mass, pH value, heat treatment conditions and mechanical load.

Since the GA unit is more hydrophilic than the LA unit, the higher the GA content in the copolymer, the faster the degradation rate. Gentile. summarized the degradation cycle of PLGA with different copolymer monomer ratios. As shown in Table 1, it can be seen that the degradation cycle of PLGA increases exponentially with the increase of LA content. When LA∶GA=50∶50, the degradation rate is the fastest, which is nearly 10 times faster than pure PLA.

What Is PLGA CAS 26780-50-7 Used For?

PLGA has become one of the most widely used degradable medical polymer materials due to its good biocompatibility, degradability and mechanical properties. In practical applications, by controlling the synthesis method and aggregate structure, the degradation rate of PLGA can be effectively regulated to obtain PLGA products that meet the actual application needs, so that it has a broader application prospect in the fields of drug controlled release, medical surgical sutures, bone tissue engineering scaffolds, etc.