Last updated on June 26, 2024

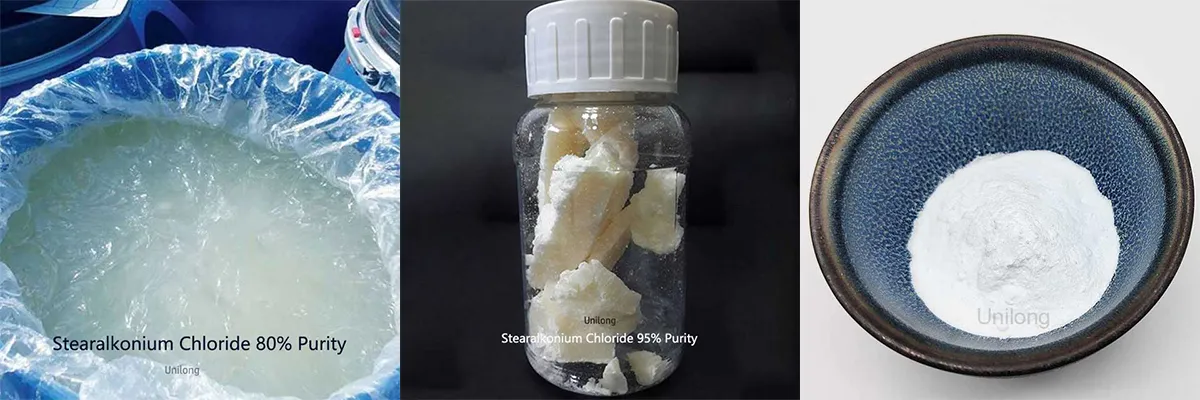

This Privacy Policy describes the policies of Unilong Industry Co., Ltd., Chemical Industrial Park of Shandong Province. email: info@unilongindustry.com, phone: +86 18653132120 on the collection, use and disclosure of your information that we collect when you use our website ( https://unilongindustry.com/ ). (the “Service”). By accessing or using the Service, you are consenting to the collection, use and disclosure of your information in accordance with this Privacy Policy. If you do not consent to the same, please do not access or use the Service.

We may modify this Privacy Policy at any time without any prior notice to you and will post the revised Privacy Policy on the Service. The revised Policy will be effective 180 days from when the revised Policy is posted in the Service and your continued access or use of the Service after such time will constitute your acceptance of the revised Privacy Policy. We therefore recommend that you periodically review this page.

Использование

We use your personal information to provide you with the services you request, to communicate with you, to resolve issues, to customize your experience, to inform you about our services and Website updates and to measure interest in our Website and Services.

Like many websites, we use “cookies” to enhance your experience and collect information about visitors and visits to our website. Please see the “Do We Use ‘Cookies’?” section below for information about cookies and how we use them.

Disclosure

We will not sell or rent your personal information to third parties for their marketing purposes without your explicit consent. We may disclose personal information to respond to legal requirements, enforce our policies, respond to claims that a posting or other content violates the rights of others, or to protect the rights, property, or safety of anyone. Such information will be disclosed in accordance with applicable laws and regulations. We may also share personal information with service providers who help us conduct our business and with members of our corporate family who may provide joint content and services and help detect and prevent potentially illegal activities. If we plan to merge or be acquired by another business entity, we may share personal information with the other business entity and require the new combined entity to comply with the provisions of this Privacy Policy with respect to your personal information.

Media

If you upload images to the website, Visitors to the website can download and extract any location data from images on the website.

Use Rights

You can access or update the personal information you have provided to us at any time by contacting us at info@unilongindustry.com.

Security

We consider information an asset that must be protected and use a number of tools to protect your personal information from unauthorized access and disclosure. However, as you may be aware, third parties may be able to unlawfully intercept or access transmissions or private communications. Therefore, while we work very hard to protect your privacy, we do not promise, and you should not expect, that your personal information or private communications will always remain private.