2008

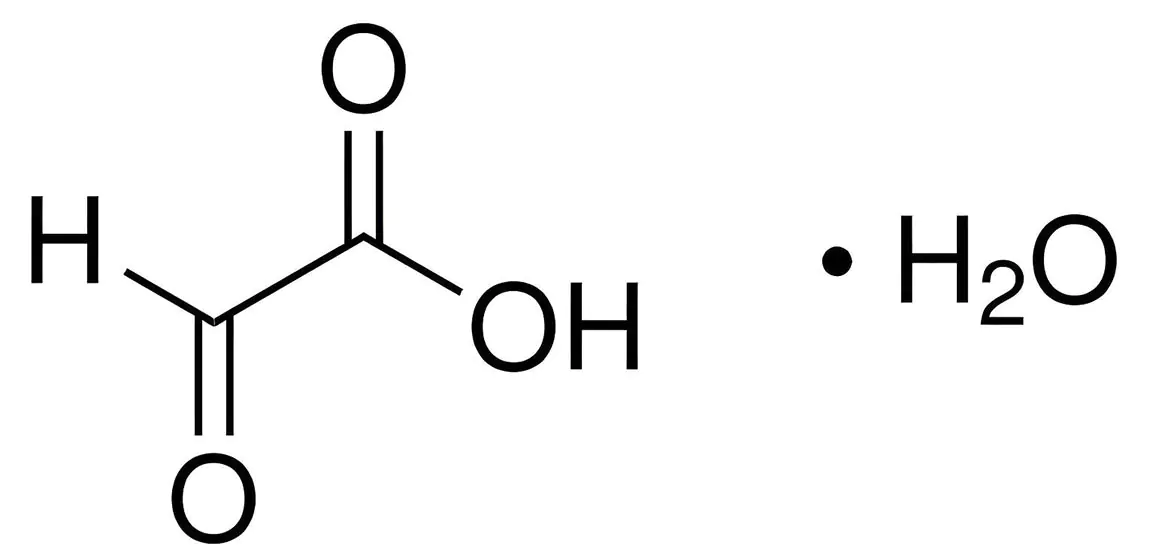

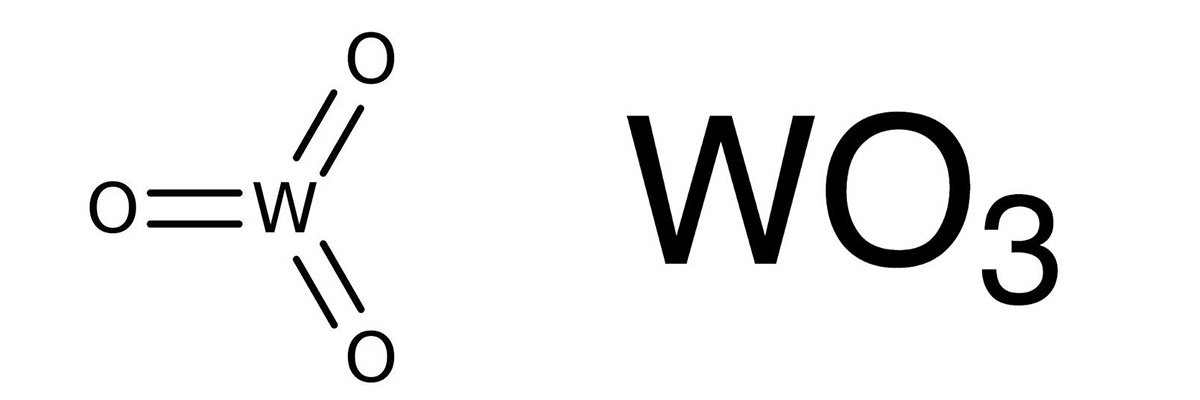

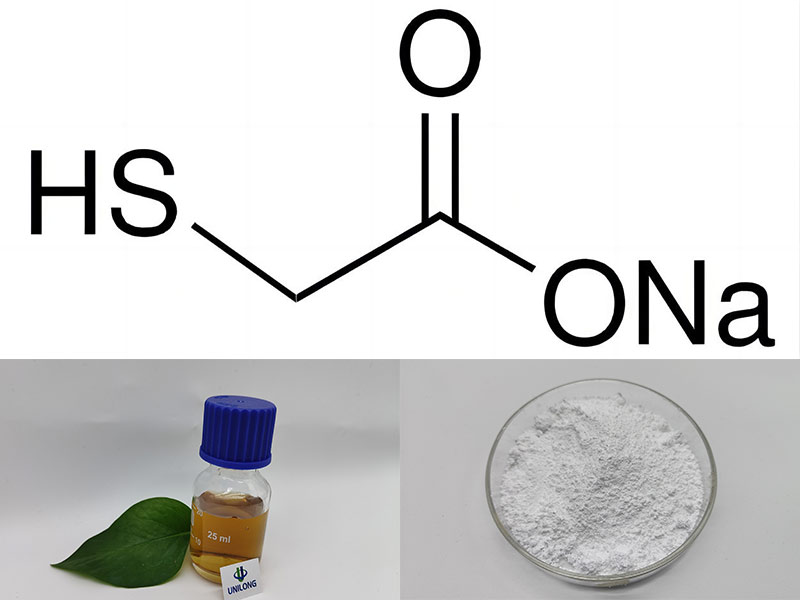

Unilong Industria fundada en 2008, la empresa es un cultivo de alta tecnología de la empresa química. Se comenzó a centrarse en los productos químicos finos. Más tarde, se transfiere completamente a la R & D y la producción de la nueva serie de productos.

2011

Unilong la Industria ha pasado el IS014001 sistema de gestión ambiental de la certificación, y está catalogada como una empresa de alta tecnología en la Provincia de Shandong, que ofrece condiciones favorables para el desarrollo futuro de la empresa.

2012

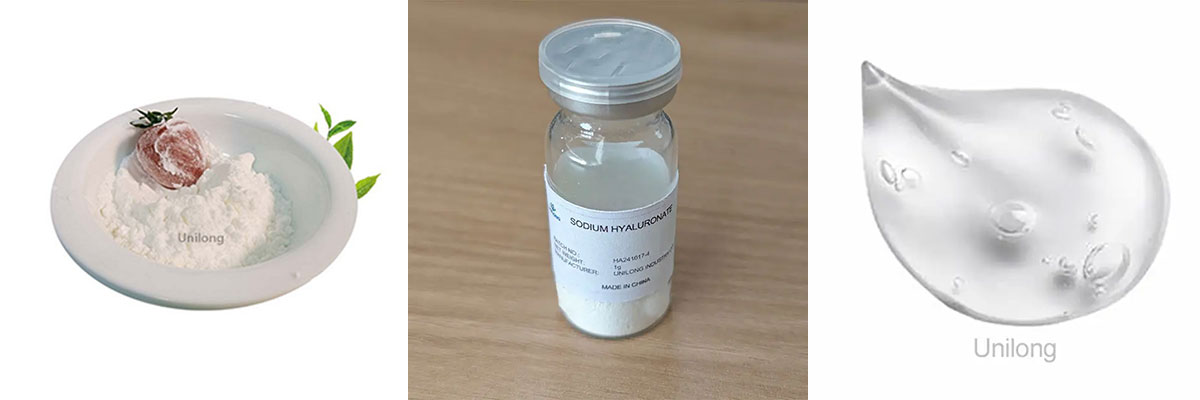

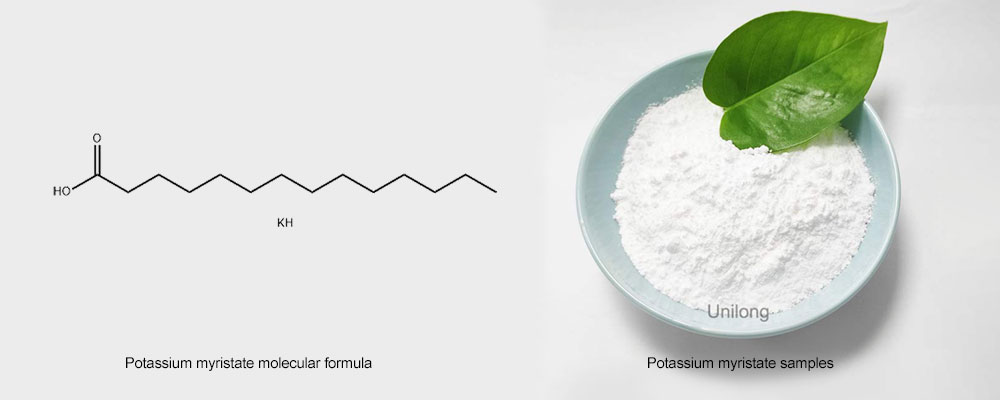

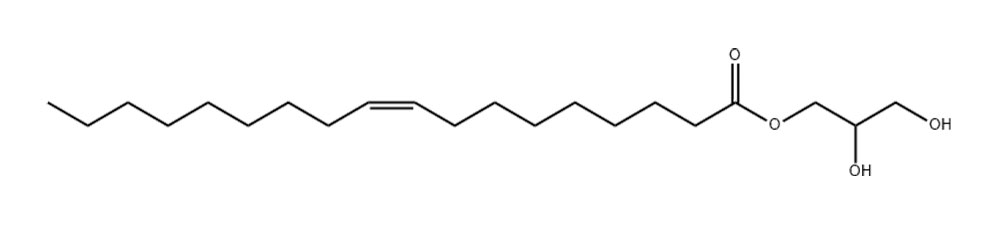

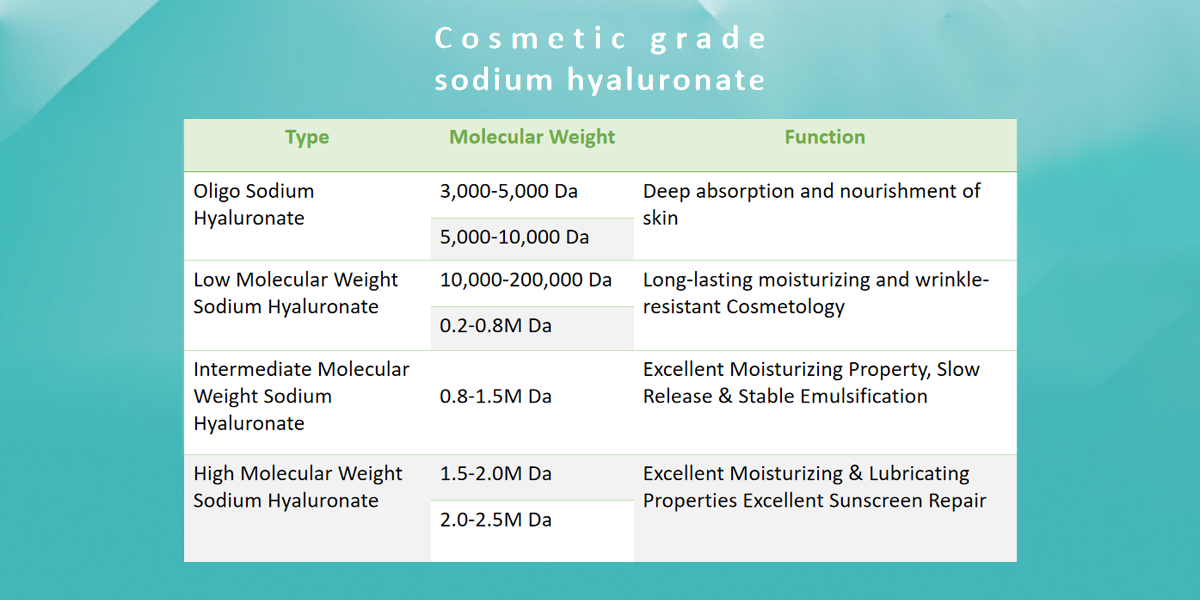

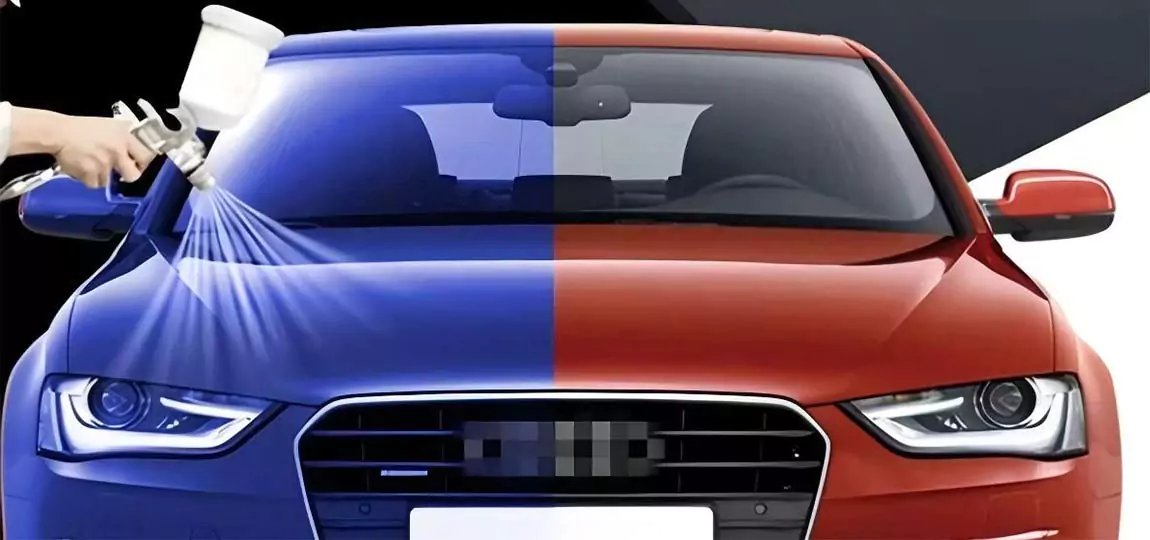

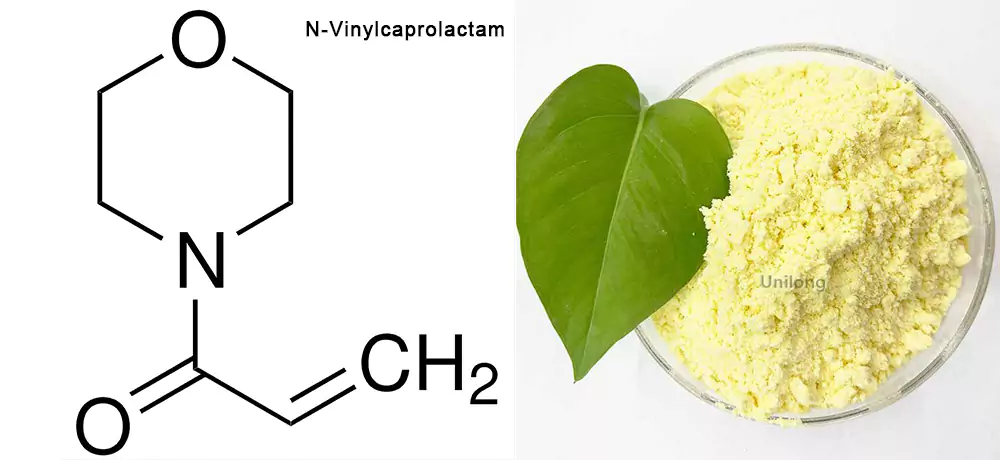

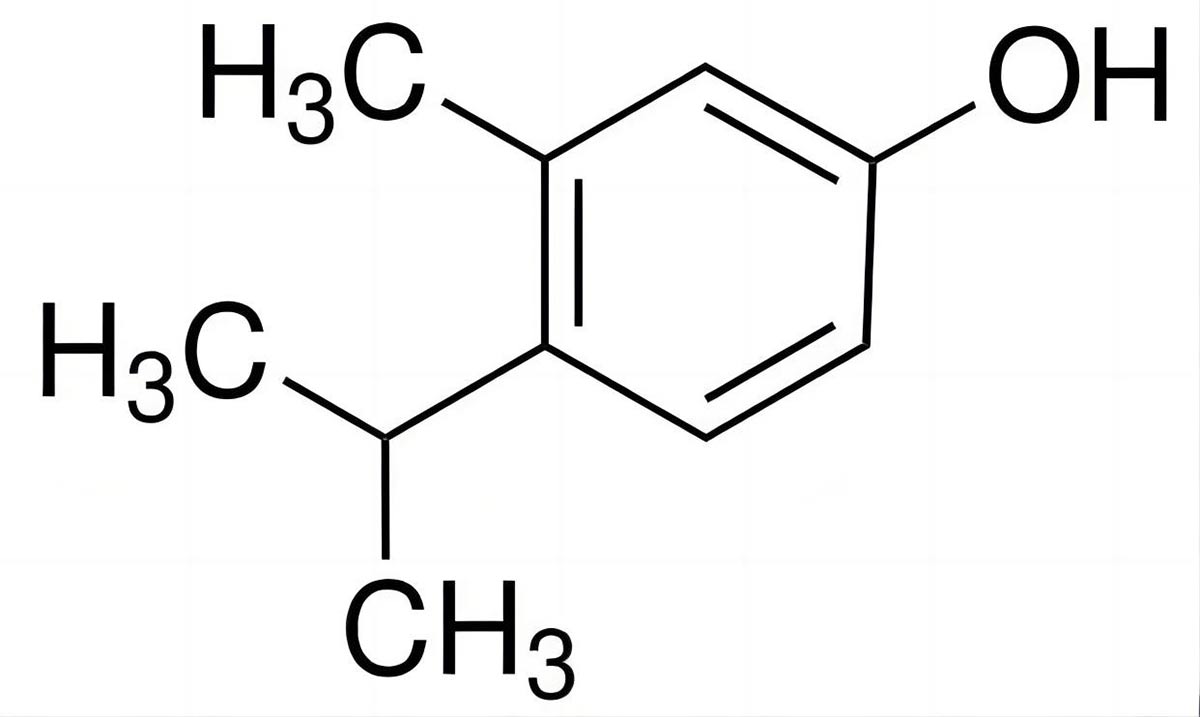

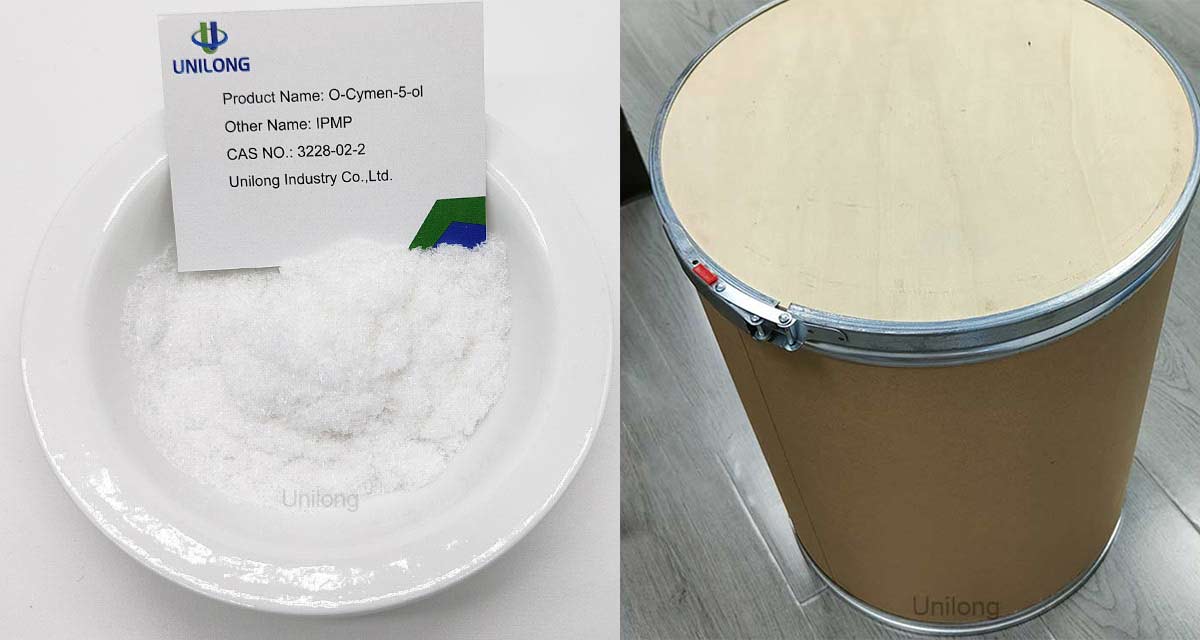

La compañía abrió de Shandong sucursal y comenzó a expandirse la dirección de producción relacionados con la cosméticos materias primas y diario de materias primas químicas.

2016

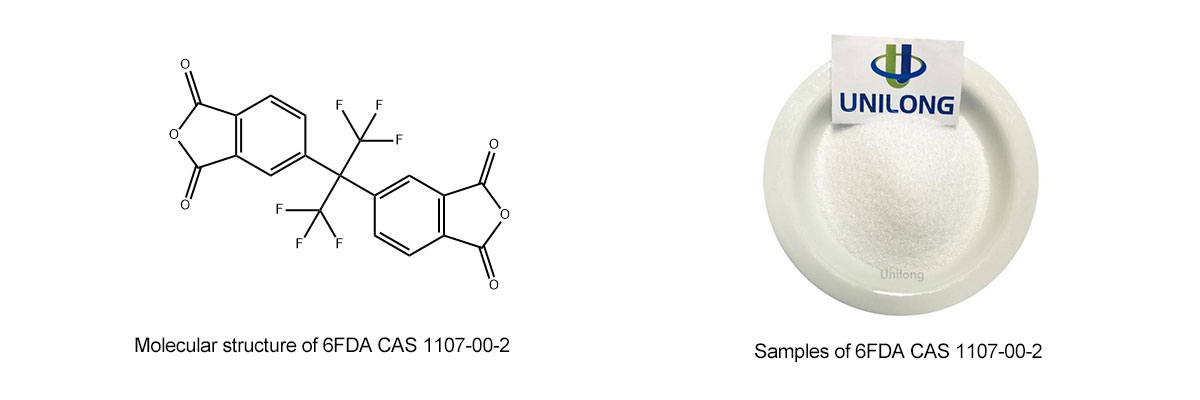

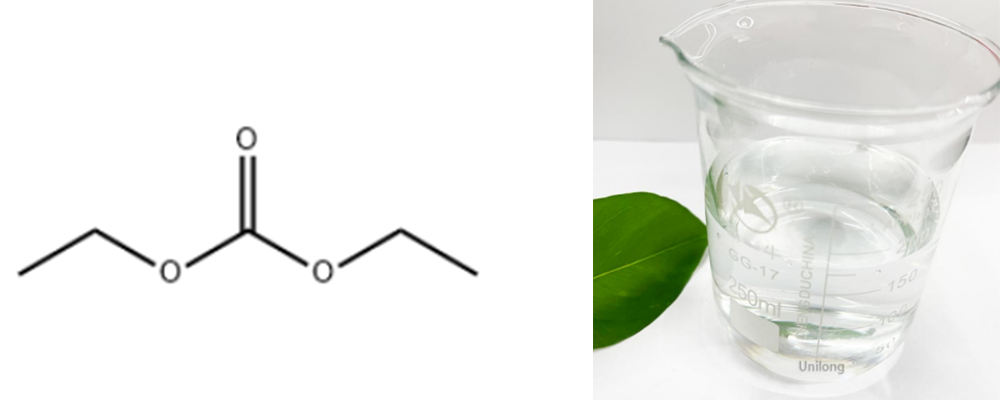

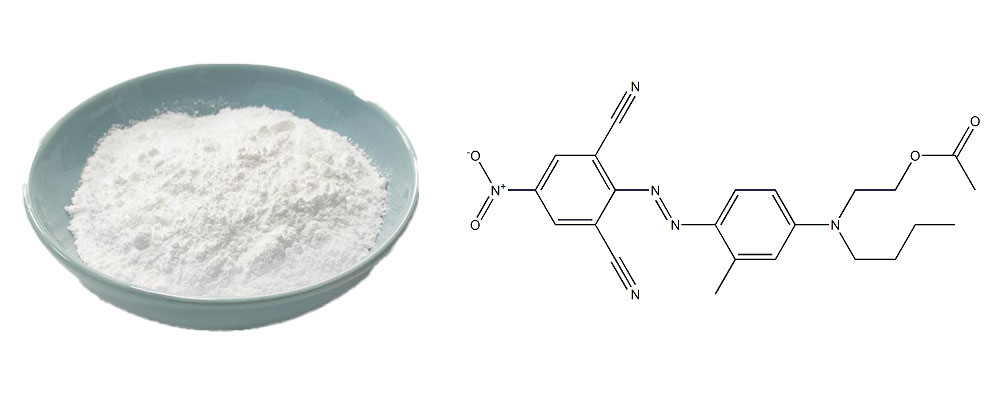

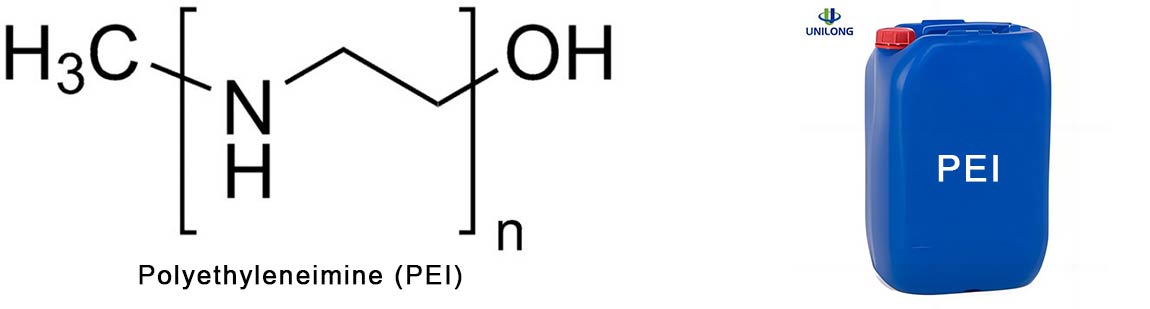

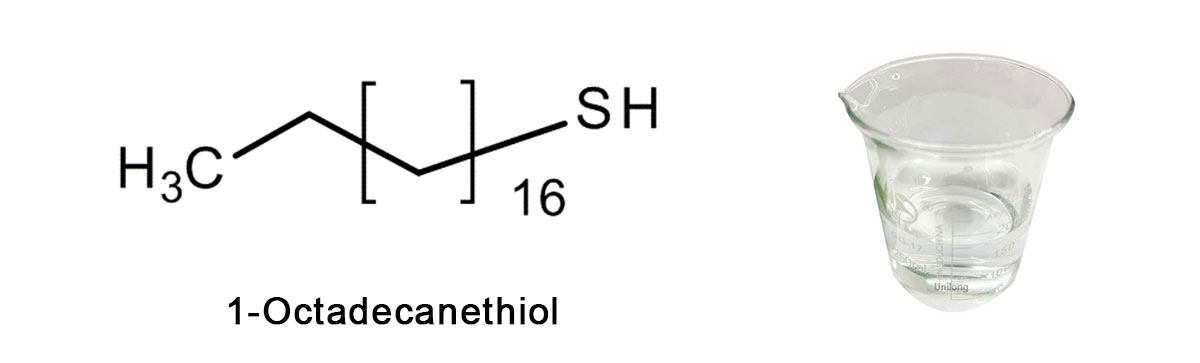

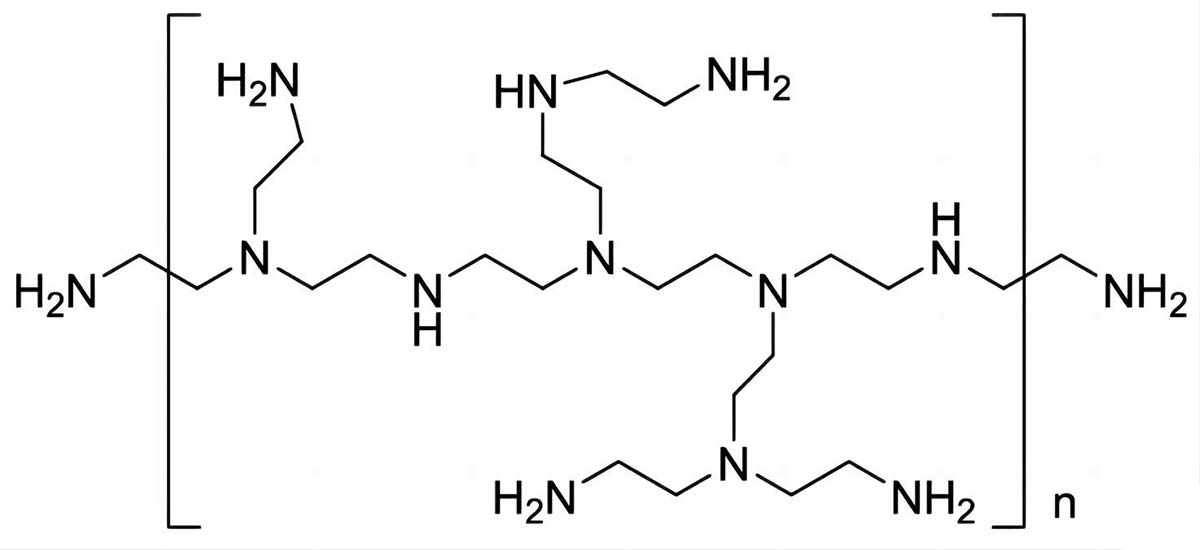

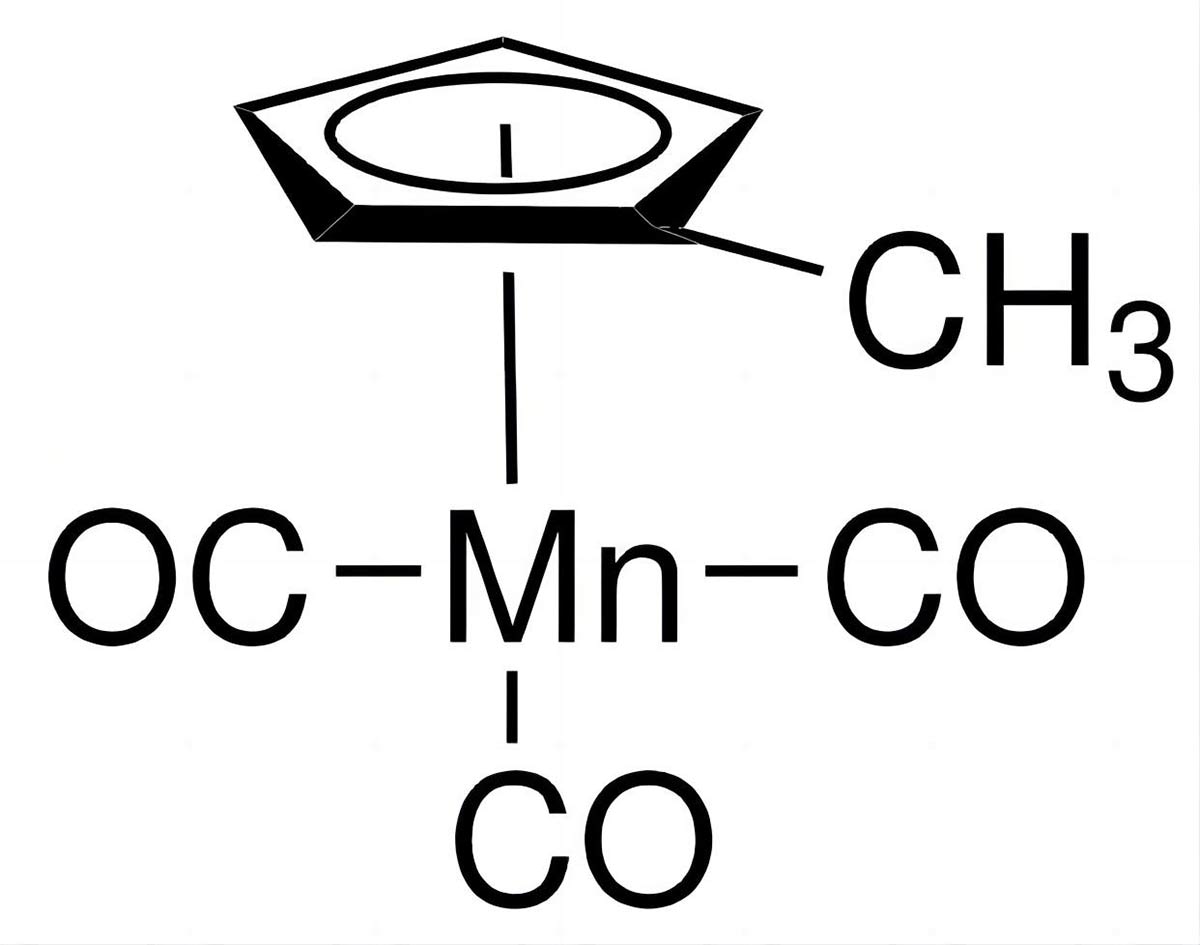

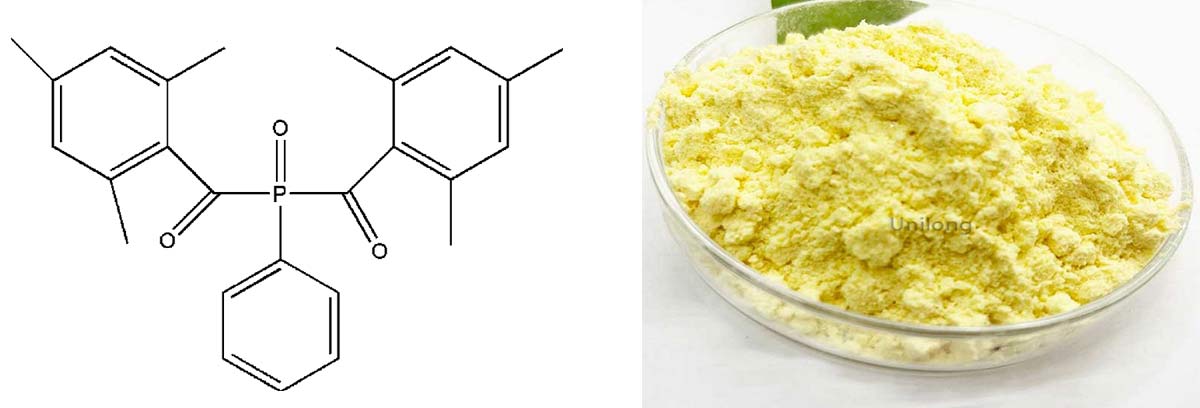

La empresa abre un polímero de fábrica, ámbito de negocio cubre el R&D, producción y ventas de diarios de química de materias primas, materiales biodegradables y de la impresión en 3D de los materiales.

2017

Ya hemos logrado relacionados con los productos certificados como ISO9001, BPI DIN NTSQP, etc. Hay un refrán en el mercado "Uli-ECO, te va a gustar".

2020

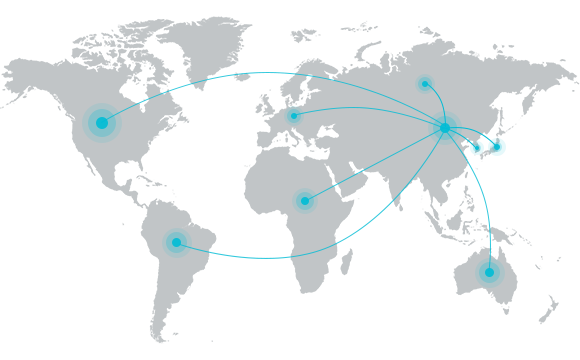

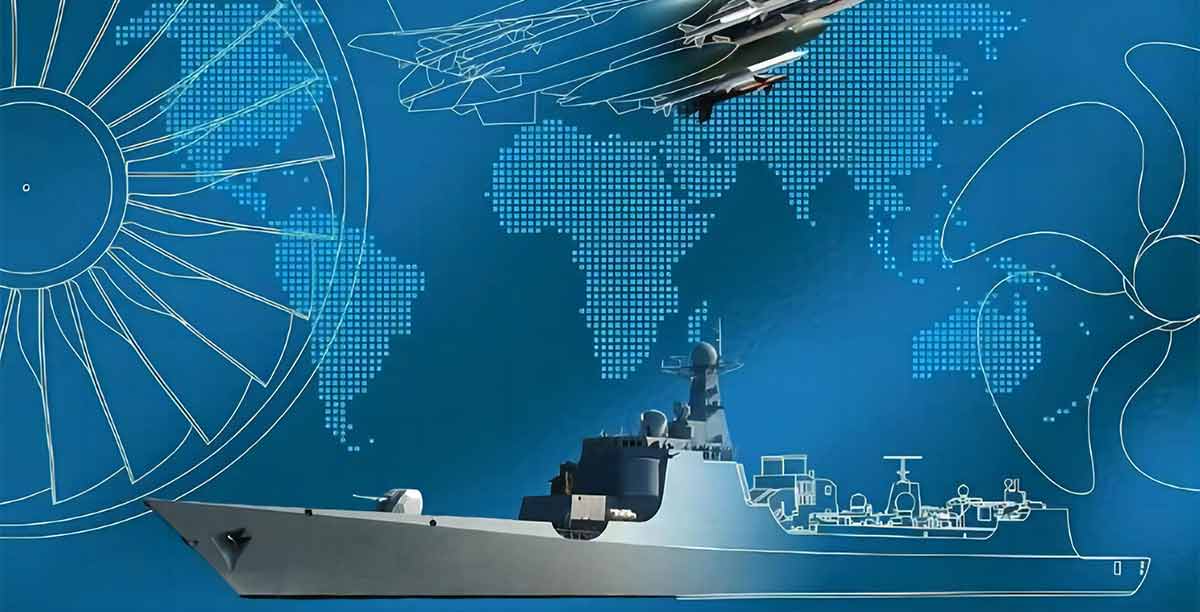

Unilong de la Industria se ha convertido en una one-stop comprador y el proveedor del servicio para muchos clientes de todo el mundo. En la actualidad, sus productos se exportan a América del Norte y sudamérica, Europa, Asia, Australia, África del Sur y otras decenas de países y regiones.

2022

Unilong es mantener las relaciones con la parte superior de alta tecnología de laboratorio y participado en más nuevas y renovables de material de investigación.Con bajas emisiones de carbono de protección ambiental, no tóxico nuevos materiales de la dirección.