DMP-30, also known as Tris(dimethylaminomethyl)phenol (CAS 90-72-2), is a highly efficient tertiary amine compound that serves as an accelerator and curing agent in a wide range of chemical formulations. With its strong catalytic activity, thermal stability, and compatibility with different resin systems, DMP-30 plays a crucial role in the performance and durability of coatings, adhesives, and composite materials.

Whether used in epoxy resin curing, polyurethane foams, or high-performance industrial coatings, DMP-30 ensures faster curing, improved crosslinking, and enhanced mechanical strength. This article explores why Tris(dimethylaminomethyl)phenol has become an indispensable component in modern material science and why many DMP-30 manufacturers and Tris(dimethylaminomethyl)phenol suppliers continue to expand its global use.

As a professional DMP-30 manufacturer and Tris(dimethylaminomethyl)phenol supplier, we provide high-purity products with consistent quality to meet the needs of different industrial applications.

I. What is DMP-30 (Tris(dimethylaminomethyl)phenol)?

DMP-30 is a tertiary amine-based phenolic compound with the chemical formula C15H27NO3 and CAS 90-72-2. It appears as a pale-yellow to light brown liquid with a mild amine odor.

It combines the characteristics of an organic amine catalyst and a phenolic stabilizer, making it a multifunctional additive in polymer systems.

Key Properties of DMP-30:

High catalytic activity for epoxy and polyurethane curing reactions.

Excellent thermal and chemical stability.

Good solubility in epoxy resins, polyols, and solvents.

Promotes uniform crosslinking and hardness development.

Provides long pot life and controlled curing rate.

II. Applications of DMP-30

1. Coatings

In the coatings industry, DMP-30 acts as an accelerator that promotes epoxy curing reactions, improving coating hardness, adhesion, and chemical resistance.

It is widely used in:

Industrial protective coatings

Marine and floor coatings

High-solids and powder coatings

By accelerating the curing rate, Tris(dimethylaminomethyl)phenol helps achieve a smoother film surface and excellent long-term gloss retention.

2. Adhesives and Sealants

In epoxy adhesives, DMP-30 improves bonding strength and curing efficiency, ensuring reliable adhesion between metals, plastics, ceramics, and composites.

It’s used in:

Structural adhesives for automotive and aerospace

Electrical and electronic encapsulants

Construction bonding and repair systems

Its catalytic efficiency makes it ideal for high-performance adhesive formulations where both fast curing and durability are essential.

3. Composites and Electrical Applications

Tris(dimethylaminomethyl)phenol is also an important accelerator in epoxy composite and electrical casting systems.

It enhances resin curing depth, reduces internal stress, and ensures dimensional stability in finished parts.

Typical applications include:

Electrical potting and insulation materials

Fiber-reinforced composites

Resin transfer molding (RTM) systems

Because of its high catalytic activity, DMP-30 ensures consistent curing throughout thick sections and complex structures.

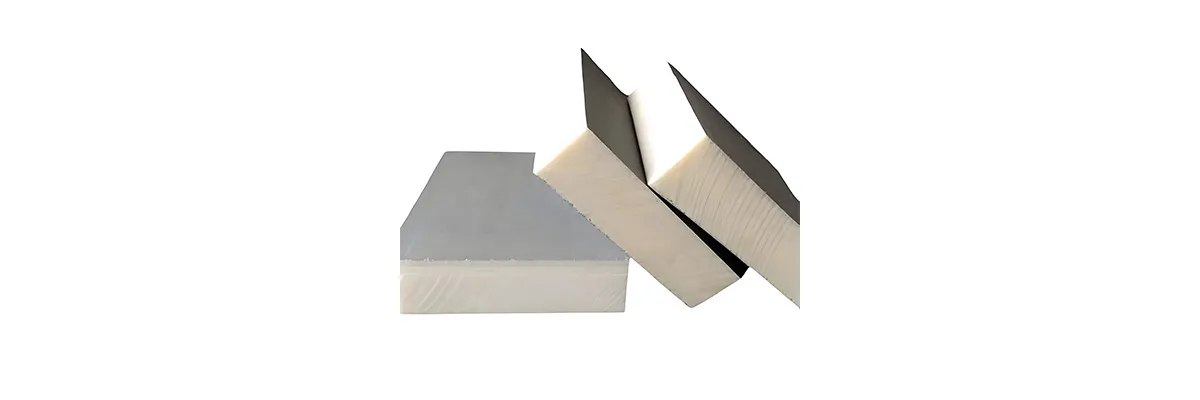

4. Polyurethane and Foam Systems

In polyurethane (PU) foams, DMP-30 functions as a co-catalyst to regulate the reaction between polyol and isocyanate.

It enhances foam cell uniformity, mechanical strength, and dimensional stability.

This makes it a valuable additive in rigid foams, insulation materials, and flexible foams used in furniture and packaging.

III. Benefits of Using DMP-30

Fast Curing: Accelerates epoxy crosslinking without sacrificing pot life.

Excellent Mechanical Strength: Improves tensile, flexural, and adhesion properties.

Thermal & Chemical Stability: Ensures long-lasting protection in harsh environments.

Wide Compatibility: Works well with different curing systems and resin types.

IV. How to Use DMP-30

DMP-30 is generally added at 0.5–3% by weight of the total resin system, depending on formulation and required curing speed.

It can be used alone or in combination with other curing agents such as polyamines, anhydrides, or imidazoles.

To ensure stability and reactivity, store DMP-30 in a tightly closed container at room temperature and avoid exposure to moisture or strong acids.

V. We Are a Reliable DMP-30 Manufacturer and Supplier

As a trusted DMP-30 manufacturer and Tris(dimethylaminomethyl)phenol supplier, we provide high-quality materials that ensure consistent performance in your formulations.

Our CAS 90-72-2 DMP-30 is available in industrial-grade and high-purity versions, suitable for coatings, adhesives, composites, and polyurethane applications.

Our Advantages:

Strict quality control and batch consistency

Technical support for customized formulations

Global export service with competitive pricing

Fast delivery and flexible packaging options

We are committed to helping our customers optimize their product performance with reliable and efficient Tris(dimethylaminomethyl)phenol (DMP-30) solutions.

IV. 结论

DMP-30 (Tris(dimethylaminomethyl)phenol, CAS 90-72-2) has become a cornerstone additive in modern polymer chemistry.

Its unique combination of catalytic efficiency, stability, and versatility makes it ideal for coatings, adhesives, and composites applications.

As industries continue to pursue higher performance materials, the role of DMP-30 will only become more essential — supported by reliable DMP-30 manufacturers and global Tris(dimethylaminomethyl)phenol suppliers dedicated to consistent quality and innovation.